Why Regenerated Transformer Oil Is Important for Reliable Power Systems

The critical function of regenerated transformer oil in guaranteeing the reliability of power systems can not be overemphasized. By bring back the oil's intrinsic chemical and physical properties, the regrowth procedure considerably boosts its dielectric strength and thermal performance.

Relevance of Transformer Oil

Transformer oil plays a critical duty in the efficient operation of electrical transformers. By providing thermal conductivity, transformer oil dissipates warmth generated during electric operation, which is important for maintaining optimum operating temperature levels and prolonging the life-span of the devices.

In addition, transformer oil functions as a barrier versus wetness and air, which can bring about oxidation and degradation of transformer products. The visibility of pollutants in the oil can substantially impair its protecting residential or commercial properties, causing functional inefficiencies and possible tools failure. Normal monitoring and maintenance of transformer oil are for that reason important to ensuring the continued efficiency of transformers.

The quality and make-up of transformer oil are extremely important, as they directly affect the dependability and efficiency of the electrical systems in which they operate. Understanding the importance of transformer oil is necessary for utilities and markets reliant on durable power facilities, stressing the need for efficient administration and regeneration processes to maintain oil honesty gradually.

Advantages of Regeneration Process

In addition, the regeneration process alleviates the deterioration of oil, which can lead to increased oxidation and acid development. This not only boosts the dependability of the oil but additionally reduces the risk of transformer failures due to insulation malfunction. The boosted quality of restored oil enables transformers to operate at optimal degrees, inevitably causing boosted power efficiency and lowered functional expenses.

In addition, the regrowth process adds to maintaining the total wellness of the power system. Transformers can run much longer without the need for oil replacement, therefore lessening downtime and maintenance efforts. In recap, the regrowth process supplies significant advantages by enhancing the long life and efficiency of transformer oil, making certain that power systems run accurately and effectively gradually.

Environmental Influence and Sustainability

The regrowth procedure of transformer oil significantly minimizes ecological problems related to oil disposal and waste administration. Conventional disposal methods for made use of transformer oil present significant risks, including dirt contamination and water pollution. By regrowing oil, these risks are markedly lowered, as the process recycles existing resources rather than adding to lose buildup.

Moreover, regenerated transformer oil can be reused in different applications, which over at this website promotes a circular economy. This not only lessens the need for virgin oil extraction-- a procedure that can be eco destructive-- but likewise conserves natural deposits. The regeneration procedure itself employs innovative purification and purification techniques that eliminate hazardous contaminants, making sure that the end product fulfills or exceeds industry requirements for efficiency and security.

Enhancing Transformer Efficiency

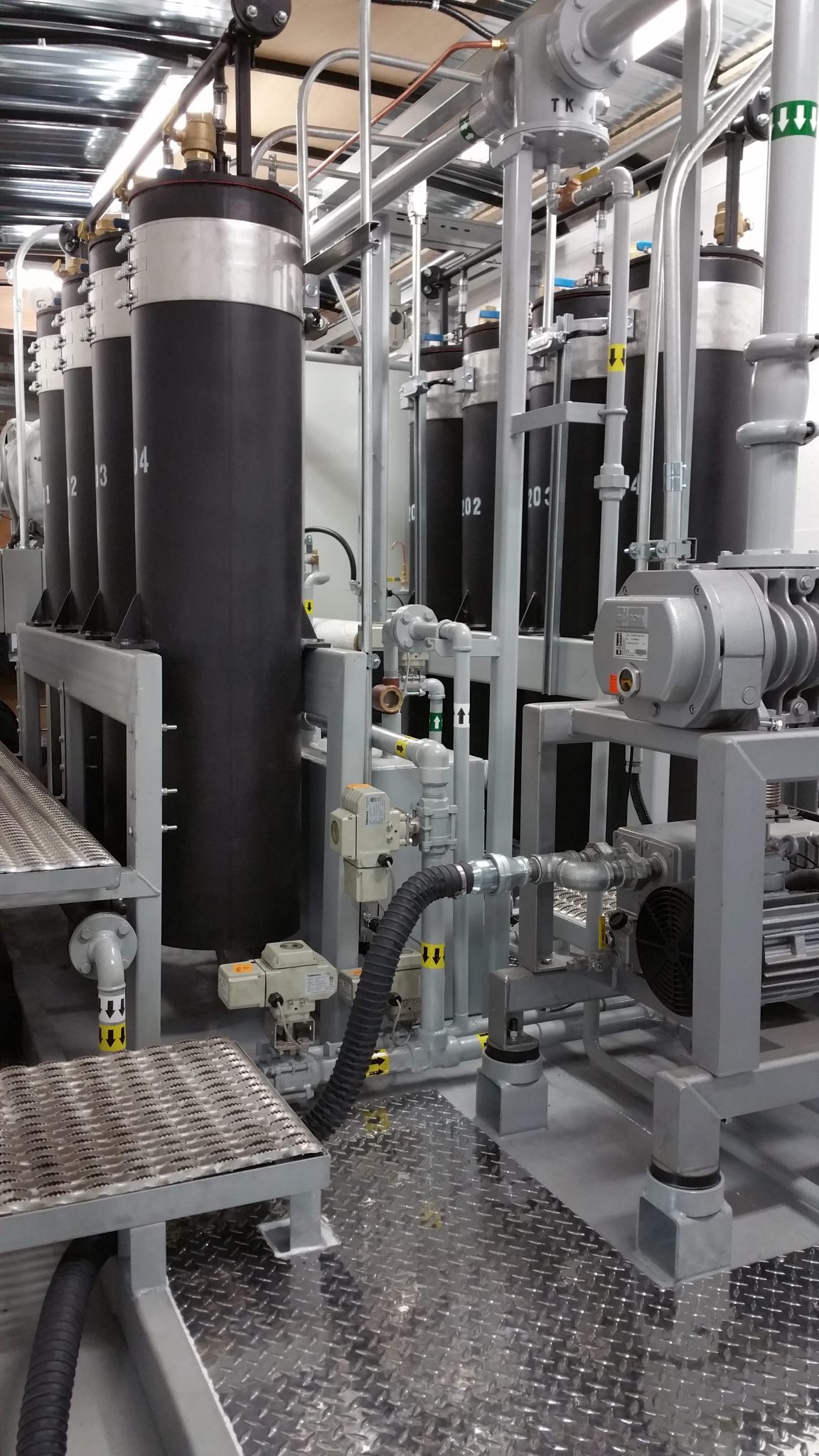

Considerable renovations in transformer performance can be accomplished with the use of regenerated transformer oil. This oil, produced through sophisticated filtration processes, dramatically improves the electric insulation properties of transformers. By eliminating pollutants and pollutants that typically jeopardize performance, regrowed oil makes sure premium dielectric strength, decreasing the danger of electric failures.

Additionally, regenerated transformer oil displays enhanced thermal conductivity, which facilitates efficient warm dissipation. This characteristic is vital for keeping optimal operating temperature levels, thereby prolonging the life-span of transformers and decreasing the likelihood of overheating - Reclaimed Transformer Oil. Enhanced thermal monitoring also adds to the overall integrity of power systems

In addition, the chemical security of regrowed oil stops the formation of corrosive acids and sludge, which can detrimentally influence transformer elements. By maintaining a cleaner internal environment, this oil decreases upkeep requirements and extends solution periods.

Cost-Effectiveness and Efficiency

In terms of cost-effectiveness and performance, regrowed transformer oil presents an engaging option to conventional oils. The regrowth process not just eliminates contaminants yet also brings back the oil's original residential or commercial properties, extending its practical lifespan. This long life translates right into decreased regularity of oil replacement, thereby reducing operational prices in time.

Moreover, the usage of regrowed oil can considerably reduce power losses related to ineffective insulating fluids. Its superior dielectric buildings guarantee optimum performance, improving the integrity of power systems. Because of this, businesses benefit from lower upkeep costs and reduced downtime, cultivating a more effective operational atmosphere.

Final Thought

In verdict, the regeneration of transformer oil plays an important duty in guaranteeing the dependability and performance of power systems. By recovering the necessary chemical and physical residential or commercial properties of the oil, this procedure enhances dielectric strength and thermal conductivity, eventually lowering the risk of insulation malfunction. Furthermore, the environmental benefits related to reusing sources add to sustainability initiatives, while cost-effectiveness and enhanced performance highlight the requirement of using regenerated transformer oil in contemporary electrical infrastructure.

Transformer oil plays a crucial duty in the reliable procedure of electrical transformers. Regular surveillance and upkeep of transformer oil are therefore essential to ensuring the proceeded efficiency of transformers.

The regrowth procedure of transformer oil dramatically eases environmental issues connected with oil disposal and waste administration. By prolonging the lifecycle of transformer oil, the power and sources normally consumed in creating brand-new oil are significantly reduced.Significant enhancements in transformer efficiency can be achieved with the usage of regenerated transformer oil.

Comments on “The Duty of a Transformer Oil Regeneration Plant in Modern Industry”